Technical Center / Pilot Plants

Home

- / GIG Karasek Portfolio Overview

- / Technical Center & Pilot Plants

Trials, scale up and R&D at the Technical Center from GIG Karasek

The laboratory at the GIG Karasek Technical Center

High-grade test infrastructure for individual trials

Since 2008 it has been possible to conduct tailormade trials for thermal separation processes - and recently also for CO2 valorization – at the GIG Karasek Technical Center in Gloggnitz, Austria. The technical center offers a state-of-the-art test infrastructure for individual tasks and is equipped with following testing facilities:

- Laboratory evaporator

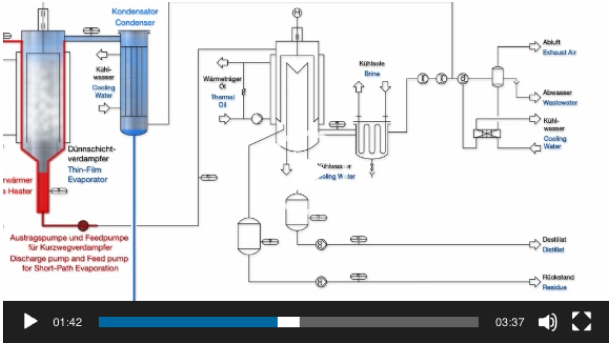

- Thin-film evaporator

- Short-path evaporator

- Horizontal thin-film dryer

- High-viscous evaporator

- Falling-film evaporator

- CO2 electroreduction system

The entire equipment can be operated with different process parameters in parallel generating operating data. Relying on its long-standing expertise our team elaborates optimum process conditions for the industrial plants and research objectives of our customers.

Our capabilities:

- Production of samples for customer analyses

- Trials with provided sample substances

Test your own product on small scale! - Laboratory trials

- Pilot trials with demonstration plants

- Comprehensive trial reports including scale-up engineering

- Toll evaporation

Your advantages:

- Safeguard of planned investments thanks to meaningful test results

- Testing of new feed streams, temperature- and concentration ranges as well as wiper types

- Basis for achieving process guarantees (e.g. degree of purity, final concentration, etc.)

- Optimum conditions thanks to state-of-the-art equipment

- High flexibility and tailormade trials

Components can be combined/configured according to requirements - Qualified personnel with extensive expertise in thermal separation and CO2 valorization (electroreduction)

- Wide-ranging offer – from concept development to advice for investment decisions

The product is distributed continuously over the entire circumference of the heating wall. Using special wiper elements the wall contact is renewed constantly and the product stream simultaneously transported. The blades do not touch the heating jacket, but prevented crusting or clogging of the heating surface by massively built, arranged with defined gap wiper elements.