Thin Film Dryer - horizontal & vertical

Home

- / GIG Karasek Portfolio Overview

- / Thin Film Dryer - horizontal & vertical

The dryer solution for streams containing solids

The thin film dryer is a special thin film evaporator type.

There are two types of thin film dryers, the vertical and the horizontal dryer. If conventional systems reach their limits when it comes to heat-sensitive products, the successful thin-film evaporator principle ensures gentle processes.

Based on their wealth of experience and knowledge from separation technology, our experts realize high-performance vertical and horizontal thin-film dryers, which convince both economically and process technically.

Thin Film Dryer - horizontal & vertical

Overview

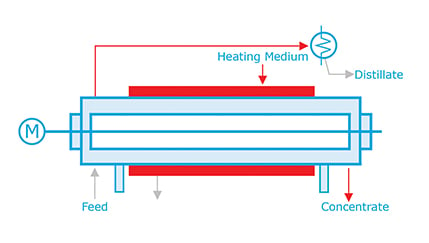

Function

The product is continuously distributed over the entire circumference of the heating wall. With the help of special wiper elements, the wall contact is constantly renewed and the product flow is simultaneously transported further.

The rotor blades do not touch the heating jacket, but prevent encrustation or blocking of the heating surface by means of solidly constructed wiper elements arranged with a defined gap. This wiper design enables liquid feed products to be dried up to powder form.

The various units can be used individually or in combination, allowing the operator to benefit from the advantages of different evaporator designs.

Applications

The Thin Film Dryer is mainly used in the waste industry, chemical, pharmaceutical and in the food industry. Products such as:

- Sludges (sewage sludge, process sludge, industrial sludge and muncipial sludge)

- Chemical products (preproducts and intermediates)

- Suspensions

- Pastes

- Moisture solids

- Saline solutions

- Products of fatty acid industry

Advantages

- Granted high dryness

- Minimal product loss

- Product protection and purity

- Gentle evaporation due to short residence and permanent product circulation

- No deposits on the heating surfaces due to mechanical cleaning

- Reduced maintenance through clever design in the bearing and mechanical seal area