Destillation & Rectification

Home

- / GIG Karasek Portfolio Overview

- / Distillation

© GIG Karasek

Distillation vs. Rectification

In distillation, liquid mixtures are separated by evaporation followed by condensation. This process leverages the different boiling points of the components to obtain defined fractions.

When the boiling points are close together, rectification is used - a multistage form of distillation with reflux operation. It takes place in a column divided into a stripping section and a rectification section, allowing for particularly high separation efficiency through repeated mass and heat exchange.

ADVANTAGES

-

Efficient separation of complex compound mixtures

-

High separation efficiency

-

High product purity

-

Continuous operation in a compact design

-

Proven, low-maintenance technology

-

Flexible integration with multi-effect evaporation systems or mechanical vapor recompression (MVR) to increase overall process efficiency

Application areas

Distillation and rectification systems are used across a wide range of industries for the purification, recovery, and separation of complex compound systems. These include, among others:

-

Purification of alcohols

Separation and recovery of methanol, ethanol, isopropanol, and glycerin from alcohol-water mixtures. -

Purification of organic substances

Efficient separation and purification of lactic acid, acetone, and butyl acetate in aqueous mixtures. -

Purification of condensates

Efficient purification of condensates from the pulp industry using strippers. -

Solvent recovery

Recovery of solvents from mixtures such as solvent-water or solvent-fatty acid systems. -

Special applications

For the separation of trichloroethylene and oil, as well as for the treatment of alternative fuels and biogenic compound systems.

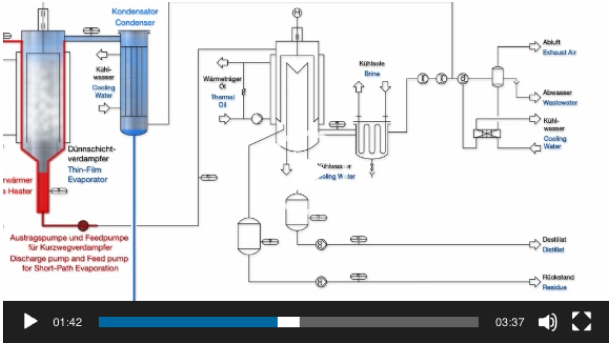

The product is distributed continuously over the entire circumference of the heating wall. Using special wiper elements the wall contact is renewed constantly and the product stream simultaneously transported. The blades do not touch the heating jacket, but prevented crusting or clogging of the heating surface by massively built, arranged with defined gap wiper elements.

Visit our Newsroom!

Here you can find the latest NEWS, our EVENT CALENDAR or further INSIGHTS featuring our key topics.