VarioVAP - Multi-source Heat Recovery

Home

- / GIG Karasek Portfolio Overview

- / VarioVAP Multi-Source Heat Recovery

Diverse industrial waste heat streams - centrally recovered with VarioVAP

Rising energy costs, ambitious climate targets, and limited resources demand consistent and efficient use of energy - especially in sectors where sustainable industrial processes are being advanced strategically .

In numerous areas, waste heat, often in the form of steam, remains unused, whether due to low energy content or temperatures, small partial streams or a lack of technical integration. The result: valuable energy is lost and primary energy is being wasted.

One goal: Zero Waste Heat

With VarioVAP, GIG Karasek offers a holistic solution for utilizing industrial waste heat: heat streams from diverse sources are intelligently consolidated and converted to be used.

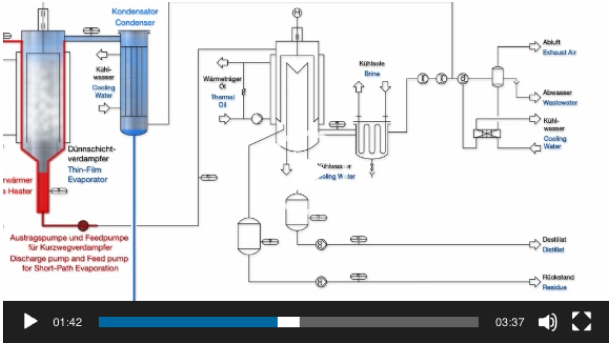

Sample layout of a VarioVAP-Systems with a plate falling-film evaporator and an open heat pump system © GIG Karasek

Zero waste heat through centralization

VarioVAP transformes both large and even the smallest waste heat streams, previously considered uneconomical, into valuable energy resources.

When consolidating these varied heat streams, differences in temperature, pressure or energy content become insignificant.

With VarioVAP, the principle of "Zero Waste Heat" - maximizing the use of waste heat - becomes fully achievable for the first time.

© GIG Karasek

© GIG Karasek

ADVANTAGES:

-

Cost savings through reduced resource consumption - less fossil energy and cooling water

-

Decreased CO2 footprint

-

Centralized waste heat utilization - one system for multiple sources

-

Zero Waste Heat for maximum energy efficiency

-

High flexibility - scalable and fail-safe

-

Compact design, easy to retrofit and low-maintenance

Maximum energy from waste heat - with VarioVAP for industrial facilities and industrial parks.

Functional principle

At the heart of the VarioVAP system is a plate falling-film evaporator which functions as an innovative heat exchanger. Each heat source - typically exhaust steam - is fed into the fully welded evaporator through a separate line, where it is "recycled" and converted into sustainable fresh steam.

Stand-alone heat exchanger or MVR combination

The system can operate either as a stand-alone heat exchanger solution or in combination with an open heat pump system based on mechanical vapor recompression (MVR).

In the latter case, the generated steam is raised to a higher energy level and can be fed into production processes or external networks as high-quality steam depending on demand.

Thanks to the separation of the individual lamellas, steam and condensate flows remain clean and separated - even explosive media can be processed safely. The compact, vertical design also allows for space-saving integration into existing systems.

Areas of application

The VarioVAP system is ideally suited for environments with multiple waste heat streams:

-

Industrial plants: Especially effective for sectors involving thermal separation processes such as distillation, evaporation or drying - for example the chemical, food, pulp, paper or metal industries.

-

Industrial parks: Joint utilization of diverse waste heat streams from various facilities - either for reintegration into internal processes or for feeding into district heating networks.

Why GIG Karasek?

Our extensive expertise in plant engineering, thermal technology and forward-looking environmental solutions makes us a strong partner for sustainable process optimization. Whether as a stand-alone solution or an integrated system, we return your waste heat back into the process - efficiently, safely and sustainably.

Our services

-

Design and engineering of customized systems

-

Manufacturing and delivery

-

Integration into existing processes

-

Optional: Flash tank systems for liquid media

-

Installation, commissioning, maintenance and after-sales service

Retifikation

Übersicht

Einsatzgebiete

- Alkohol / Wasser

- Lösemittel / Wasser

- Lösemittel / Fettsäuren

- Trichlorethylen / Öl

- Lösemittel / Wasser aus Spinnbad für Faserindustrie

- Alternative Treibstoffe

- Methanolabscheidung aus Kondensat der Eindampfanlage

- Methanol / Wasser

- Ethanol / Wasser

- Aceton / Wasser

- Butylacetat / Wasser

- Butylalkohol / Wasser

- Glycerin / Wasser

- Milchsäure / Wasser

uvm.

Vorteile

- kontinuierliche Betriebsweise

- energetisch günstiger als eine Destillation

- platzsparend

- technisch weniger aufwändig

Energieoptimierungsmöglichkeiten

- Mehrstufige Anlagen

- Mechanische Brüdenverdichtung

- Thermische Brüdenverdichtung

Kolonneneinbauten

- Packungen

- Böden

- Füllkörper

Reboiler

- Fallfilmverdampfer

- Dünnschichtverdampfer

- Zwangsumlauf

The product is distributed continuously over the entire circumference of the heating wall. Using special wiper elements the wall contact is renewed constantly and the product stream simultaneously transported. The blades do not touch the heating jacket, but prevented crusting or clogging of the heating surface by massively built, arranged with defined gap wiper elements.

Download

Functional principle of VarioVAP: multi-source system with a plate falling-film evaporator and multi-stage compressor system. © GIG Karasek

Visit our newsroom!

Here you can find the latest NEWS, our EVENT CALENDER and further INSIGHTS featuring our key topics.

We've also published the following articles on the topic of waste heat utilization:

Industrial Waste Heat Utilization: Heat Recovery Options in Pulp Mills

Efficient Use of Waste Heat: Industrial Heat Pump as a Driving Force of the Energy Transition

Industrial Heat Pumps in Comparison: Technological Differences and Application Areas