Short-path Evaporator MINIPLANT

Home

- / GIG Karasek Portfolio Overview

- / MINIPLANT

Thermal separation of challenging substances with a high-performance stand-alone unit

The short-path evaporator MINIPLANT features the functionality of an industrial system in a compact form. It is ideally suited for on-site trials, the distillative purification of challenging substances, and the recovery of valuable materials.

Core component: Short-path evaporator

Equipped with the POWERMOL 25 short-path evaporator, the integrated condenser enables a minimal distance between the evaporation and condensation zones. This allows for particularly gentle evaporation under fine vacuum conditions. The MINIPLANT thus represents an innovative advancement of the thin-film evaporator.

Flexibility and maximum efficiency

With the MINIPLANT, plant operators have the opportunity to conduct meaningful trials directly at their production site or in their in-house research center. Processes are continuously replicated on a small scale - a decisive advantage over laboratory experiments that are based on batch operation.

At the same time, the system allows for the cost-effective and rapid production of sample products or small batches of a specific substance.

Flexible location thanks to plug-and-play

The MINIPLANT is mobile and requires only a standard power connection (400 V, 50 Hz, 25 kW). Thanks to air-cooled chillers, no external water connection is needed.

Reliable and flexible operation

The evaporator prevents fouling through continuous mechanical cleaning of the heating surface, ensuring stable operational performance. Flow rates, heating capacity, and rotor speed can be individually adjusted to achieve optimal conditions. All process data is continuously recorded, accessible, and exportable. Optional modern IIoT features are also available.

Cost-efficient purchase or leasing options

The standardized MINIPLANT design enables the acquisition of a compact, complete system at attractive conditions. Additionally, GIG Karasek offers flexible leasing models that provide further financial advantages.

ADVANTAGES

-

Meaningful trials at a location of your choice

-

Cost-effective and rapid production of small quantities/sample products

-

Gentle evaporation of temperature-sensitive, high-viscosity, and explosion-hazardous media

-

Plug-and-play principle

-

High performance and reliable operation

-

Optimizable for specific conditions

Continuous data analysis

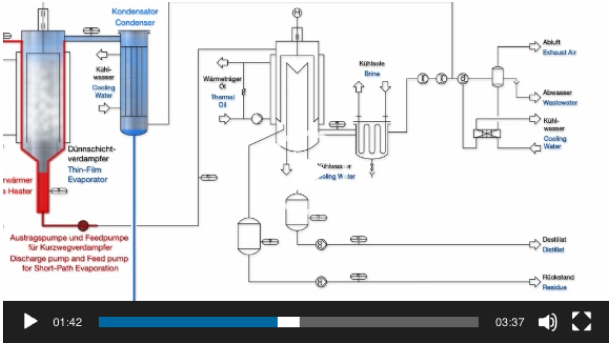

Functional principle

The feed material is continuously fed into the POWERMOL 25, distributed along the heated evaporator wall, and guided downward.

Low-boiling components evaporate, condense internally, and are discharged as distillate, while higher-boiling substances are removed as concentrate.

Gear pumps transport the distillate and concentrate into collection vessels. Non-condensed vapors and inert gases are directed into the vacuum system, with a droplet separator preventing the entrainment of high-boiling components.

Application areas

Thermally sensitive substances

The system is optimized for thermally sensitive products. Thanks to short residence times in the evaporator, thermal stress remains minimal. A fine vacuum ranging from 0.01 to 1,000 mbar enables distillation under extremely low pressure conditions.

Explosion-hazardous media

The system is ATEX-certified (2014/34/EU) and designed for handling explosion-hazardous media. Both the process area and the environment comply with ATEX II 3/3 G Ex T3 Gc X, ensuring maximum safety.

Highly viscous substances

The MINIPLANT also efficiently processes highly viscous substances with viscosities of up to 2,000 mPas.

Application examples

-

Waste oil

-

Silicone oil

-

Fatty acids

Visit our Newsroom!

Here you can find the latest NEWS, our EVENT CALENDAR or further INSIGHTS featuring our key topics.

We have published the following article on the MINIPLANT:

Technical Center / Pilot Plants

Overview

Advantage through innovation

Get to know new processes and convince yourself of innovative approaches: Our Technikum team will introduce you to the secrets of future-oriented process technology or develop new process steps as tailor-made special solutions explicitly for your challenges. Because only long-term and sustainably operated research and innovation activities provide the necessary results to be able to optimize the processes of our customers in the future.

- laboratory tests

- pilot tests

- test reports incl. Scale Up

Test your product on a small scale

Many products require the definition of the optimal plant configuration and the inspection of the operating data. GIG Karasek offers you the uncomplicated possibility to test-produce your product on our laboratory-scale equipment. Instead of off-the-shelf technology, we realize customized scalable systems tailored to your processes and research goals.

Pilotplants

Pilot Plants close the gap between laboratory and production facilities. We also offer perfect solutions here.

The product is distributed continuously over the entire circumference of the heating wall. Using special wiper elements the wall contact is renewed constantly and the product stream simultaneously transported. The blades do not touch the heating jacket, but prevented crusting or clogging of the heating surface by massively built, arranged with defined gap wiper elements.