Modernization Measures

Home

- / GIG Karasek Portfolio Overview

- / Modernization measures

Keeping existing production facilities competitive with revamping, retrofitting, and debottlenecking

Even small, targeted changes can make a significant impact when it comes to the following topics:

-

Maintaining equipment and systems at peak performance throughout their entire service life or extending their operational lifespan

-

Adapting production processes to new conditions and requirements

-

Increasing production efficiency

-

Reducing the carbon footprint by implementing technologies for decarbonization and defossilization.

Lamella bundle replacement at Sappi Saiccor, South Africa @ GIG Karasek

Range of services

-

On-site assessment and inventory review

-

Detailed examination and inspection

-

Development of a strategy/concept for meaningful modernization

-

Supply of replacement equipment and replacement of obsolete components

-

Installation- and commissioning monitoring (warranty coverage for new components supplied by GIG Karasek)

Revamping

Selective maintenance and condition improvement measures offer an effective way of modernizing individual machines and systems that are getting on in years.

Individual apparatuses – either from our in-house production or from other manufacturers – are professionally refurbished and reinstalled according to the „old-meets-new“ principle.

Retrofitting

If a specific conversion or retrofit of a system is required, individual existing appliances are replaced with new components or additional equipment is integrated into the system.

Debottlenecking

The reasons for unsatisfactory operation are often to be found in specific bottlenecks in the process. Through a comprehensive analysis of the overall operating conditions, GIG Karasek uncovers the problem areas and eliminates them with targeted measures.

Individual measures are necessary depending on the initial situation. Compared to a new system, however, the investment is still significantly smaller.

Focus - bundle replacement

Bundle replacement - retrofitting

End-of-life bundles are replaced with new bundles. The system conditions – including the plate dimensions and evaporation surface – remain the same. With this simple but effective conversion of existing falling film evaporators, your system is modernized in the shortest possible downtimes and at the lowest possible cost.

Bundle replacement - debottlenecking

Problem areas in the process are examined and eliminated in a targeted manner, but with more extensive measures. End-of-life bundles are replaced and also the evaporation surface is redimensioned.

Learn more about GIG Karasek’s lamella technology!

Visit our Newsroom!

Here you can find the latest NEWS, our EVENT CALENDAR or further INSIGHTS featuring our key topics.

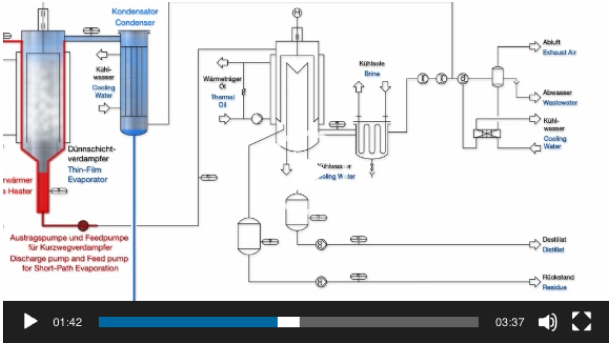

The product is distributed continuously over the entire circumference of the heating wall. Using special wiper elements the wall contact is renewed constantly and the product stream simultaneously transported. The blades do not touch the heating jacket, but prevented crusting or clogging of the heating surface by massively built, arranged with defined gap wiper elements.