CO2 Utilization Technologies

Home

- / GIG Karasek Portfolio Overview

- / CO2 utilization technologies

CO2 Valorization – Transforming carbon dioxide from a problem into an opportunity

GIG Karasek holds the patent for a pioneering CO2 electroreduction system

Converting captured carbon dioxide into valuable industrial products with ECO2CELL

GIG Karasek has made it its mission to provide effective solutions to the global problem of immense CO2 emissions and the associated massive impact on the world‘s climate.

As an expert in industrial plants and plant engineering, we focus on innovative processes for CO2 utilization and are pioneers in the field of electrochemical conversion technology.

From problem to opportunity with ECO2CELL

GIG Karasek has developed ECO2CELL for converting captured carbon dioxide into valuable chemicals and fuels and holds the patent for this pioneering technology.

Thanks to our many years of know-how in plant engineering and process technology, we have the ultimate expertise to implement customer-specific solutions for CO2 conversion.

The success of our process is groundbreaking and has already been successfully demonstrated on a pilot scale. With our ECO2CELL Lab Plant, comprehensive tests can be carried out directly on industrial plants or in the research facility.

Advantages

-

Wide range of end products

-

Zero-emission technology through the use of water and electricity from renewable sources

-

Easy scaling, modular design

-

Mild process conditions

(ambient temperature and pressure) -

Hydrogen does not need to be supplied to the process

CO2 valorization

ECO2CELL Lab Plant

Would you like to know more? Let's discuss how our solution can be used for your application.

End products

-

Methanol

-

Synthesis gas

-

Formic acid

-

Ethylene

-

More upon request

The technology is perfectly suited for all industrial processes – especially in carbon-intensive sectors.

Functional principle

The ECO2CELL unit uses CO2 , water, and electricity in an electrocatalytic process to produce higher-value carbon compounds.

Applying an electrical voltage causes the reduction of CO2 at the cathode and the oxidation of water to oxygen at the anode. Depending on the voltage applied and the use of different catalysts, different end products are produced.

Areas of application

-

All industrial processes – especially in carbon-intensive sectors

-

Cement industry

-

Biogas production

-

Steel industry

-

Petrochemical industry

-

Paper and pulp production

Our services

-

Development of customized CO2 conversion solutions

-

Design and construction of turnkey plants

-

Process optimization and scale-up

-

Consulting

Retifikation

Übersicht

Einsatzgebiete

- Alkohol / Wasser

- Lösemittel / Wasser

- Lösemittel / Fettsäuren

- Trichlorethylen / Öl

- Lösemittel / Wasser aus Spinnbad für Faserindustrie

- Alternative Treibstoffe

- Methanolabscheidung aus Kondensat der Eindampfanlage

- Methanol / Wasser

- Ethanol / Wasser

- Aceton / Wasser

- Butylacetat / Wasser

- Butylalkohol / Wasser

- Glycerin / Wasser

- Milchsäure / Wasser

uvm.

Vorteile

- kontinuierliche Betriebsweise

- energetisch günstiger als eine Destillation

- platzsparend

- technisch weniger aufwändig

Energieoptimierungsmöglichkeiten

- Mehrstufige Anlagen

- Mechanische Brüdenverdichtung

- Thermische Brüdenverdichtung

Kolonneneinbauten

- Packungen

- Böden

- Füllkörper

Reboiler

- Fallfilmverdampfer

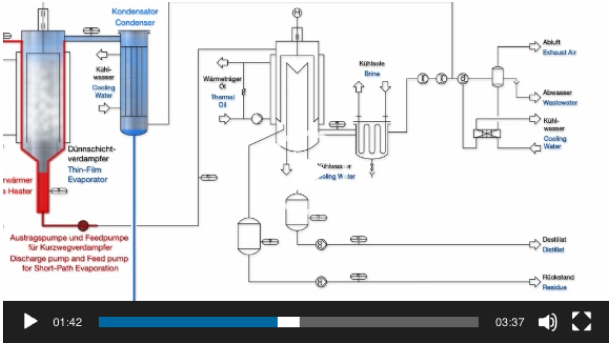

- Dünnschichtverdampfer

- Zwangsumlauf

The product is distributed continuously over the entire circumference of the heating wall. Using special wiper elements the wall contact is renewed constantly and the product stream simultaneously transported. The blades do not touch the heating jacket, but prevented crusting or clogging of the heating surface by massively built, arranged with defined gap wiper elements.

Visit our newsroom!

Here you can find the latest NEWS, our EVENT CALENDER or further INSIGHTS featuring our key topics.

We've also published the following articles on the topic of CO2 utilization technologies:

-

New technologies for converting CO2 and why GIG Karasek opts for electrochemical reduction

-

The New CO2 Economy: CCU Technologies as Enablers of a Low-Carbon Future

Download our comprehensive CO2 Utilization Whitepaper!