HSEQ

Home

- / GIG Karasek Portfolio Overview

- / HSEQ

Health, Safety, Environment & Quality

Through our HSEQ commitment, we take responsibility - for our employees, our customers, and our environment.

GIG Karasek’s HSEQ program represents an integrated management system that holistically unites health, safety, environmental protection, and quality.

Our goal is to exceed regulatory requirements, minimize risks, and foster a living culture of continuous improvement.

Our commitment

We adhere to the highest standards across all areas - from occupational safety and environmental protection to product and service quality. Through targeted initiatives, we create a safe, healthy, and sustainable work environment, promote the responsible use of resources, and ensure customer satisfaction around the globe.

Our focus areas

Health: Promoting employee well-being through prevention, training, and safe working conditions.

Safety: Preventing accidents through proactive measures and continuous monitoring.

Environment: Sustainable use of resources and reduction of environmental impact beyond legal requirements.

Quality: Ongoing improvement and innovation to ensure the highest standards in product and service quality.

Certifications - our proof of quality

Since 2024, GIG Karasek’s company-wide management system has been successfully certified according to EN ISO 9001:2015, EN ISO 14001:2015, and ISO 45001:2018 - a clear expression of our commitment across all HSEQ areas.

An overview of our current certifications:

Retifikation

Übersicht

Einsatzgebiete

- Alkohol / Wasser

- Lösemittel / Wasser

- Lösemittel / Fettsäuren

- Trichlorethylen / Öl

- Lösemittel / Wasser aus Spinnbad für Faserindustrie

- Alternative Treibstoffe

- Methanolabscheidung aus Kondensat der Eindampfanlage

- Methanol / Wasser

- Ethanol / Wasser

- Aceton / Wasser

- Butylacetat / Wasser

- Butylalkohol / Wasser

- Glycerin / Wasser

- Milchsäure / Wasser

uvm.

Vorteile

- kontinuierliche Betriebsweise

- energetisch günstiger als eine Destillation

- platzsparend

- technisch weniger aufwändig

Energieoptimierungsmöglichkeiten

- Mehrstufige Anlagen

- Mechanische Brüdenverdichtung

- Thermische Brüdenverdichtung

Kolonneneinbauten

- Packungen

- Böden

- Füllkörper

Reboiler

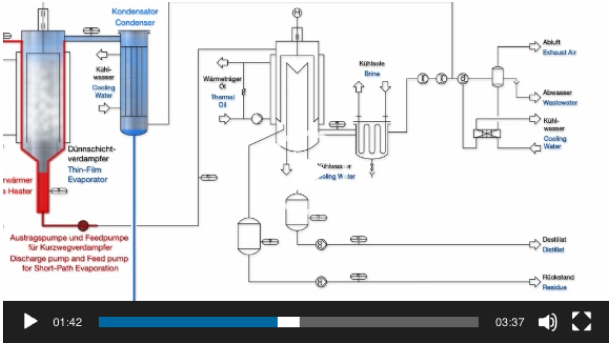

- Fallfilmverdampfer

- Dünnschichtverdampfer

- Zwangsumlauf

The product is distributed continuously over the entire circumference of the heating wall. Using special wiper elements the wall contact is renewed constantly and the product stream simultaneously transported. The blades do not touch the heating jacket, but prevented crusting or clogging of the heating surface by massively built, arranged with defined gap wiper elements.

Download

Visit our newsroom

Here you can find the latest NEWS, our EVENT CALENDER and further INSIGHTS featuring our key topics.