Inhalte

1. VarioVAP: A centralized solution for multiple waste heat streams

2. Applications of VarioVAP heat recovery

3. VarioVAP: Multi-source heat recovery in a single unit

4. Maximize waste heat recovery – integrated or standalone

5. Heat source requirements for VarioVAP operation

7. Conclusion: multi-source heat recovery for zero waste heat

1. VarioVAP: A centralized solution for multiple waste heat streams

At the core of the VarioVAP system is an innovative plate falling-film evaporator, engineered specifically for utilizing multiple waste heat sources simultaneously. Instead of utilizing each source separately, VarioVAP consolidates both large and small waste heat flows from various processes into a single, centralized recovery unit. This allows the system to tap into heat sources that were not used effectively before.

1. Multiple heat sources – one heat pump

The VarioVAP system can function either as a standalone heat exchanger system or as part of an integrated process solution in combination with Mechanical Vapor Recompression (MVR) – an open heat pump concept. Unlike traditional heat pump systems, which typically require a separate heat pump for each individual source – such as a distillation column or a flash tank – VarioVAP enables the integration of multiple waste heat streams into one single heat pump.

2. Zero Waste Heat through centralized waste heat recovery

The VarioVAP system establishes a groundbreaking foundation for the efficient and economical recovery of multiple waste heat sources within a single, centralized solution and thus setting new standards in industrial energy efficiency.

- Efficient use of large and small heat sources: Individually, small heat sources may not be economically viable. However, when aggregated, they create a usable energy potential.

- Greater efficiency through centralization: Combining multiple heat streams into one system significantly improves energy recovery economics and enhances overall plant efficiency.

- Reduced energy losses: Rather than being discarded, unused surplus heat is being captured and reused for steam generation.

With the VarioVAP system, near-total waste heat utilization ("Zero Waste Heat") becomes a reality. Even low-grade heat flows that were previously discarded can now be converted into fresh steam. The underlying technology unlocks entirely new opportunities for sustainable and cost-effective energy utilization in industrial operations.

2. Applications of VarioVAP heat recovery

Thanks to its flexible and high-efficiency technology, the VarioVAP system enables effective waste heat recovery across a wide range of industrial scenarios – from individual large-scale production facilities to multi-tenant industrial parks.

1. Industrial facilities

The greatest potential for the VarioVAP system lies in large-scale industrial plants, particularly those utilizing thermal separation processes. Its cross-industry applicability allows it to convert waste heat from operations such as distillation, evaporation, or drying into valuable steam. This makes it especially advantageous in energy-intensive sectors where substantial amounts of waste heat are typically lost – such as the chemical industry, food and beverage manufacturing, pulp and paper production, and metallurgical processing.

2. Industrial parks

A particularly promising area of application is industrial parks, where multiple companies can benefit from shared waste heat recovery. The VarioVAP system allows for the central collection of diverse heat streams, which can then be reused within the same production processes or exported into municipal district heating networks.

Advantages for industrial parks:

- Collective utilization: Companies from different industries benefit jointly from centralized waste heat recovery.

- Economic value: Participants reduce energy costs and may generate additional revenue by feeding surplus steam into district heating systems.

- Flexibility: The system can be expanded as new businesses join the industrial park or additional heat sources become available.

- Sustainability: Waste heat recovery reduces the industrial park’s carbon footprint and supports progress toward Zero Waste Heat.

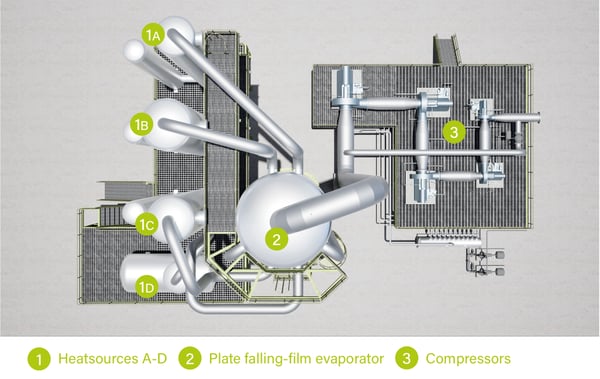

Figure 1: Example image of a VarioVAP system. © GIG Karasek

3. VarioVAP: Multi-source heat recovery in a single unit

The innovative waste heat recovery system combines multiple heat sources into one compact, integrated unit. Each individual heat source is routed through separate, fully welded lamellae, ensuring that vapors and condensates remain isolated and product purity is maintained. Thanks to its closed, gasket- and seal-free design, even explosive vapors can be safely processed in combination with non-explosive media. The vertical configuration minimizes space requirements and allows for flexible integration into existing plant layouts.

Compared to conventional designs, the technology offers three major advantages:

- Lower capital expenditure: A compact design and economies of scale reduce CAPEX per kilogram of steel.

- Fewer components: Just one unit, a single circulation pump, and fewer instruments and valves.

- Simplified maintenance: Fewer spare parts and significantly shorter maintenance times.

Figure 2: VarioVAP waste heat recovery for four heat sources. © GIG Karasek

4. Maximize waste heat recovery – integrated or standalone

The VarioVAP system offers a flexible and cost-effective solution for industrial waste heat recovery – either as an integrated process component or as a standalone heat exchanger. It reduces primary energy consumption, boosts overall energy efficiency, and lowers operating costs.

1. VarioVAP as an integrated process solution

In this configuration, the VarioVAP system is seamlessly integrated into existing process lines without disrupting ongoing operations. While the primary process continues as usual, VarioVAP captures available waste heat and converts it into usable energy.

Simple integration

Installation requires minimal effort with primarily requiring a connecting supply line (vapors or fluids) to the VarioVAP system and interfacing with the existing plant infrastructure.

Key Advantages

- No modifications to core production systems required

- No need for separate heat pumps at each waste heat source

- Uninterrupted process operation during installation

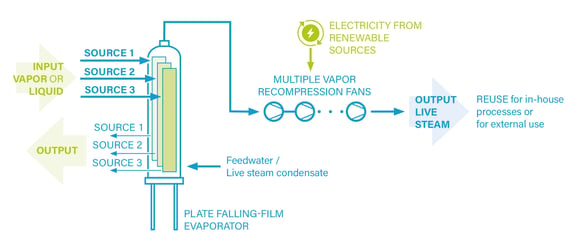

How it works

- Heat sources with varying compositions, temperatures, pressures, or even explosive vapors are routed into the plate falling-film evaporator via separate lines.

- Inside the evaporator, waste heat is converted into steam. Each heat source flows through its own isolated lamella or bundle to ensure separation and process safety.

- The resulting condensate is collected separately and can be redirected back into the upstream process as reflux.

- The generated steam is raised to a higher energy level via Mechanical Vapor Recompression (MVR) and can then be reused for internal or external applications.

Economic efficiency

The cost per ton of steam produced by mechanical vapor recompression decreases with higher throughput, as compressing larger volumes is inherently more energy-efficient than handling smaller quantities. By combining multiple heat sources into one system, the overall efficiency increases, thus boosting the economic viability of the VarioVAP solution even further.

Figure 3: The functional principle of multi-source waste heat recovery through a VarioVAP system. © GIG Karasek

2. VarioVAP as a standalone heat exchanger

VarioVAP can also be operated without a compressor, functioning solely as a high-efficiency heat exchanger. This stand-alone solution is ideal for customers who do not require steam generation but still want to recover heat from multiple sources to heat a secondary medium. Instead of installing three separate heat exchangers, the system consolidates all sources into a single unit, saving space, cost, and engineering complexity.

5. Heat source requirements for VarioVAP operation

To fully utilize its heat recovery potential, the VarioVAP system requires certain basic conditions from the connected heat sources:

- Type of heat source: VarioVAP is primarily designed for steam-based applications. If liquid sources (e.g., wastewater) are used, a flash tank must be added as an additional stage to convert the liquid into usable vapor for recovery.

- Minimum heat load: For economically viable operation, the combined thermal input from all connected sources should be at least 1 megawatt (MW).

- Number of heat sources: The number of heat sources that can be connected depends on the physical capacity of the evaporator. If the unit reaches its maximum size, an additional evaporator can be installed in parallel to handle more sources.

A key advantage of the VarioVAP system is its reliable performance under partial load. Even if one heat source is unavailable, the remaining heat flows continue to be recovered and utilized efficiently.

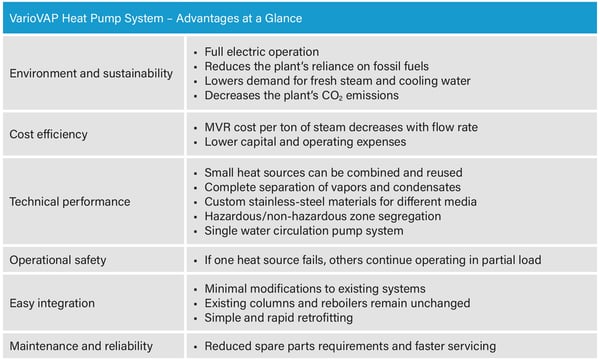

6. The advantages at a glance

Figure 4: Overview of key benefits with a VarioVAP system. © GIG Karasek

Conclusion: multi-source heat recovery for zero waste heat

The VarioVAP system is an innovative, forward-thinking solution for industrial waste heat recovery. By transforming excess heat into a valuable energy resource, it is ideally suited for large-scale production facilities and multi-tenant industrial parks. Through the consolidation of multiple heat sources, VarioVAP minimizes thermal losses and paves the way toward true Zero Waste Heat.

The benefits are convincing: the utilization of waste heat reduces primary energy consumption und thus lowers operational CO₂ emissions. Meanwhile the demand for fresh steam and cooling water decreases, conserving resources and lowering costs.

In short, the VarioVAP system offers a unique combination of sustainability, efficiency, and economic performance, and sets a new benchmark for energy-conscious industries of the future.

Visit our newsroom!

Here you'll find latest NEWS, our EVENT CALENDER and additional INSIGHTS on key topics.

We've also published the following articles on the topic of waste heat utilization:

Efficient Use of Waste Heat: Industrial Heat Pumps as a Driving Force of the Energy Transition

Industrial Heat Pumps in Comparison: Technological Differences and Application Areas

CompriVAP Heat Pump Solution: Turning Waste Heat into Value