Carbon-free steam from waste heat: Large-scale heat pump in action

BASF aims to achieve carbon neutrality by 2045 in Germany and by 2050 worldwide. A key strategic focus is the decarbonization of steam generation at its Ludwigshafen site, where approximately 14 million tons of steam are required annually – for reactors, drying, and separation processes, among others. Currently, using fossil energy for steam production generates around 1.4 million tons of CO2, accounting for nearly 30% of the site’s total emissions.

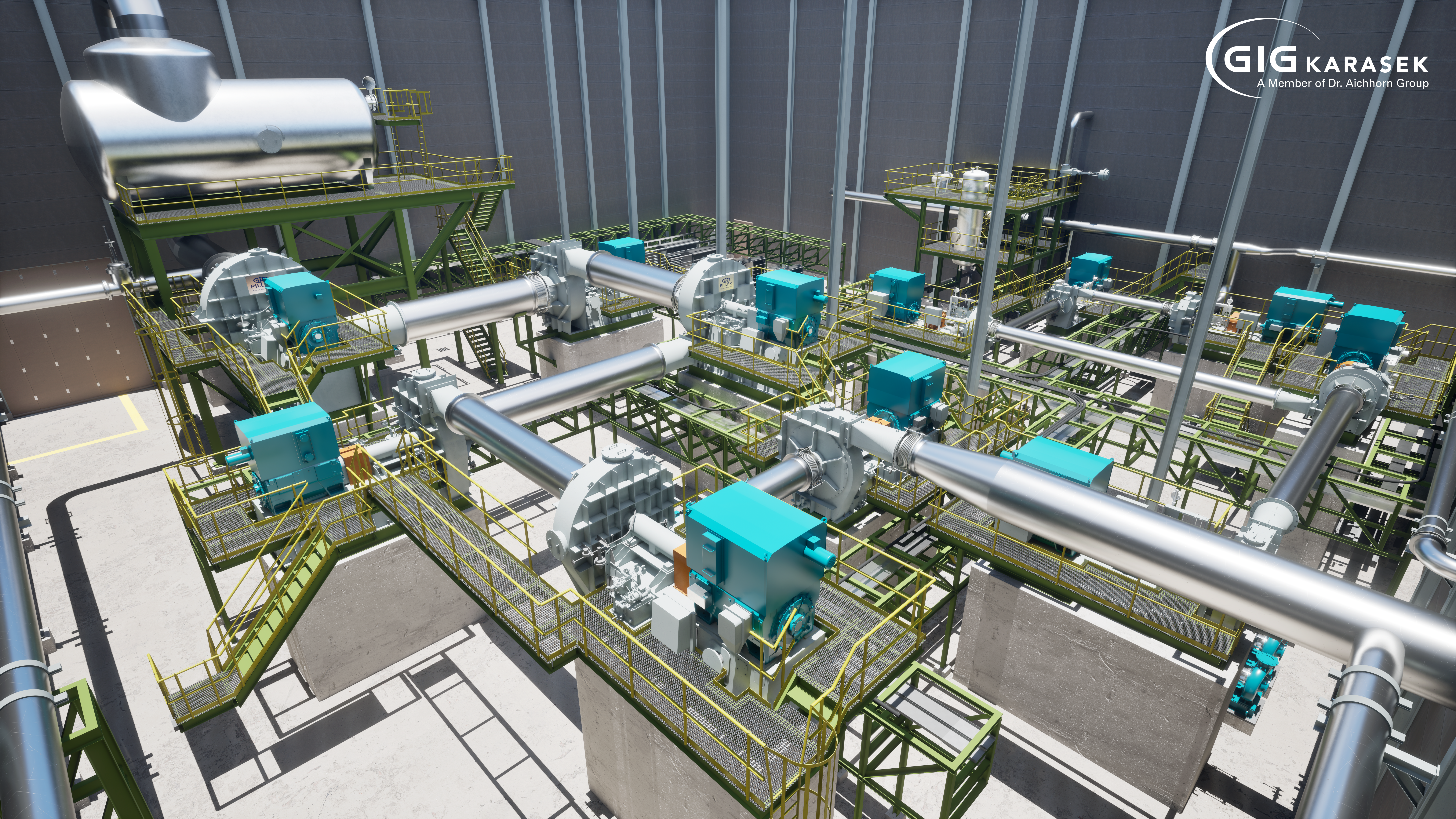

Figure 01: One of the world’s most powerful industrial heat pump systems is being implemented at BASF’s Ludwigshafen site in Germany. © BASF SE

A forward-looking system decision

BASF already covers half of the steam demand at its Ludwigshafen site through low-carbon heat recovery from chemical processes. To further decarbonize steam production, the company evaluated various steam generation concepts – placing particular emphasis on part-load capability and system availability.

The innovative CompriVAP heat pump system from GIG Karasek, combined with high-performance VapoLine® radial compressors from PILLER at the core of the setup, proved to be the optimal solution for that project. Specifically designed for industrial steam processes, the system is being deployed at this scale for the first time – both in Ludwigshafen and worldwide. Start-up is scheduled for 2027.

“The decision was driven primarily by considerations of cost-effectiveness and decarbonization,” explains Alexander Fronz, Project Manager for the large-scale heat pump project at BASF. “Equally important were the system’s high operational reliability and technical flexibility – qualities that made CompriVAP the most compelling solution for this project, given our specific requirements.“

Technology initiative with pilot character

CompriVAP harnesses previously untapped waste heat from one of the steam crackers in Ludwigshafen to produce carbon-free steam. This steam is distributed via the site-wide steam network, with formic acid production – due to government funding – serving as the primary consumer. With a thermal output of 50 MW, the system generates up to 500,000 tons of steam per year and avoids approximately 100,000 tons of CO2 emissions. As a technical pilot project on an industrial scale, it remains unique worldwide.

For Tim Lerch, Project Execution Owner at BASF, the project is more than just a technical pilot: “We’re talking about one of the most powerful industrial heat pumps worldwide – and yet, in terms of our overall CO2 emissions, it’s just a small piece of the puzzle. But an important one: Being able to implement a viable heat pump solution at this scale is, for me personally, a true milestone.”

CompriVAP: Integrated system design instead of a stand-alone solution

CompriVAP is not a single machine, but an integrated heat pump solution that combines proven technologies into one high-performance system. The concept is based on mechanical vapor recompression (MVR), where steam is brought to a higher energy level using electrically driven compressors and then supplied as process heat.

Table 01 - Key facts at a glance © GIG Karasek

| KEY FACTS about the heat pump system |

| Energy source: Previously unused waste heat from steam cracker |

| Output: Carbon-free steam (up to 500,000 t/year) |

| Capacity: 50 MW thermal |

| CO2 reduction: ~ 100,000 t/year |

| Application: Primary: Formic acid production Secondary: Other consumers within the steam network |

| Highlight: First project of this scale worldwide |

Figure 02: Visualization of the CompriVAP heat pump solution for BASF’s Ludwigshafen site. © GIG Karasek

What sets this system apart from conventional heat pumps is explained by Martin Schmid, Process Engineer at GIG Karasek and involved since the beginning of the project: “Unlike many commercially available heat pump solutions, which are primarily designed for hot water production, CompriVAP has been purpose-built from the ground up for steam generation. The technology is based on mechanical vapor recompression, which was specifically developed for steam applications – and this is exactly where it shows its full potential.”

While the individual components used are proven technologies, the real challenge lies in integrating them into a stable, continuously operating overall system. This creates specific demands for risk management – both in terms of process engineering and control strategy.

The project leads therefore deliberately chose not to pursue overly ambitious efficiency targets in order to develop a solid, feasible system. „For this first-of-its-kind application, the priority is not on pushing individual components to the limits of technical feasibility, but on delivering a fully integrated solution that ensures reliable performance,“ says Alexander Fronz.

Collaborating as equals

A project of this scale cannot be realized single-handedly. For the implementation of the large-scale heat pump, BASF deliberately relied on experienced partners in this field.

GIG Karasek – system responsibility from concept to start-up

In this project, GIG Karasek is responsible for both process development and implementation as an EPC service provider (Engineering, Procurement, Construction). Building on a preceding feasibility study, the company oversees all project phases – from conceptual design to construction and start-up of the system. Its scope of supply includes both standard components and project-specific, customized system parts.

“Our focus is not only on the optimal sizing of individual system components, but above all on their functional integration into a perfectly tuned overall system,” emphasizes Markus Putz, longtime Project Manager at GIG Karasek. “As a partner, we don’t just supply BASF with individual components – we deliver a holistic solution that proves its value technologically, economically, and operationally in the long run.”

Table 02 - Technological Highlights © GIG Karasek

| TECHNOLOGICAL HIGHLIGHTS |

| The heat pump combines proven components (falling-film evaporators, flash tank, 11-stage compressor cascade) with five innovative features: |

| Oxygen-free steam through hybrid plant design Combination of open steam generation loop and closed flash loop Falling-film evaporator separates pressure and vacuum zones, preventing oxygen ingress |

| Pure water as a safe working medium No use of other synthetic or natural refrigerants Minimized operational risks and high environmental compatibility |

| Flexible operation with part-load and restart capability Variable frequency drives for seamless adjustment to waste heat availability Standby system enables 200+ electricity price-optimized start-stop cycles per year |

| Maximum efficiency through harmonized technology Radial compressors precisely tailored to load points Additional energy utilization through integrated water preheating |

| Intelligent monitoring for high availability Condition monitoring detects deviations early and prevents failures Maintenance-friendly radial compressors reduce scheduled downtime |

PILLER Blowers & Compressors: High-performance compressors at the core

For mechanical vapor recompression, PILLER’s proven VapoLine® is used. As part of the project, the company developed an 11-stage compressor solution – divided into two cascades (6+5 units) to ensure better control of steam dynamics and to minimize risks from oxygen ingress.

As early as the initial project phase, BASF and PILLER jointly defined the requirements – a close coordination that not only enabled a specifically tailored compressor architecture but also drove internal innovations. “Every component has to fit – not only for optimal efficiency but also across a wide operating range,” emphasizes Oscar Lino Sgrott Júnior, Senior Process Engineer at PILLER. “Our goal was to reliably cover part-load conditions without bypass or recirculation – while at the same time guaranteeing the assured performance parameters. The 11 VapoLine® compressors are individually tailored to BASF’s requirements.”

One particular challenge was the transition from air-cooled to water-cooled drives during the ongoing engineering process. Nevertheless, it was possible to standardize key components such as electric motors across all units – an enormous advantage for maintenance, spare parts logistics, and overall plant availability.

The next exciting phase is already on the horizon: in about a year, all 11 machines are scheduled to be delivered and installed within just three days – a logistical milestone crucial to the project’s progress.

Stronger together in challenging phases

Close collaboration between BASF, GIG Karasek, and PILLER was a key success factor during the engineering phase – especially in critical moments such as the shift from the originally open to a hybrid system design. Within a short time, an alternative plant concept had to be developed, aligned, and integrated into the existing planning.

“The speed and professionalism with which this was mastered together was truly impressive,” recalls Alexander Fronz.

What unites all project partners is a shared understanding of the project’s importance: it is not just about technical feasibility, but about proving that large-scale industrial waste heat utilization works. As a highly visible flagship project, it is subject to considerable expectations. This makes active stakeholder management all the more critical to balance internal requirements such as cost control and schedule adherence with the project’s pilot character.

“We all feel the responsibility – and that’s exactly what creates this unique dynamic,” explains Fronz. „The teams are highly capable. We address issues with full transparen-cy and work together as equals. What unites us is the shared determination to make something truly new possible.” Without this spirit, he concludes, a project like this would not be achievable.

Outlook: A blueprint for industrial decarbonization

With the construction of the large-scale heat pump at its Ludwigshafen site, BASF is taking a new path in the industrial energy transition – technologically ambitious, economically viable, and strategically forward-looking. But the project represents more than a single milestone: it marks the starting point for a scalable solution with international relevance.

The plant demonstrates that industrial waste heat no longer has to remain an unused byproduct, but can become a strategic energy resource. The use of water as the working medium, flexible operation, and the hybrid design make the system not only innovative but also transferable to other sites and industries.

The technical experience gained in Ludwigshafen provides the foundation for future projects – both within the BASF Group and beyond. As one of the first industrial reference systems of this scale, this flagship project opens up new perspectives for decarbonizing energy-intensive processes in the chemical, food, paper, and pharmaceutical industries.

What is regarded today as a technological pioneering project will have to become standard tomorrow. The transformation toward a climate-neutral industry cannot be postponed – it starts with concrete steps here and now.

Visit our newsroom!

Here you'll find latest NEWS, our EVENT CALENDER and additional INSIGHTS on key topics.

We've also published the following articles on the topic of waste heat utilization:

Efficient use of waste heat: industrial heat pumps as a driving force of the energy transition

Industrial heat pumps in comparison: technological differences and application areas

CompriVAP heat pump solution: turning waste heat into value

Zero waste heat with VarioVAP: heat recovery form multiple waste heat sources