Case Study: Stripping Column for condensate cleaning

Home

- / GIG Karasek Insights

- / Stripping Colum ZPR Rosenthal

ZPR Mercer Rosenthal in Germany produces bleached market pulp on the basis of spruce and pine using the kraft pulp process.

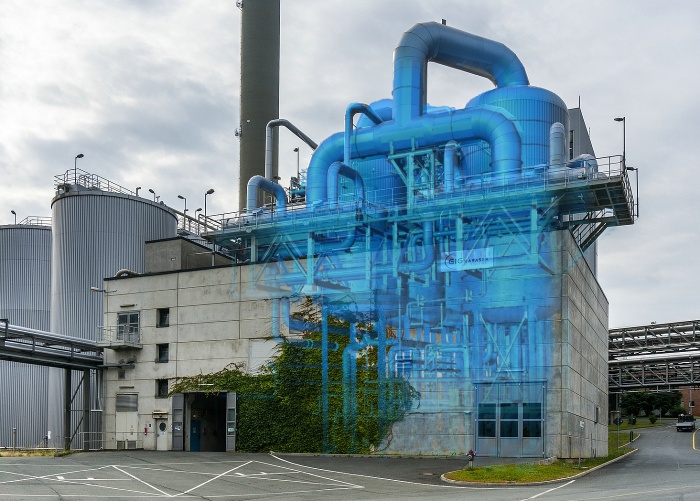

GIG Karasek is building once again an ideal customized solution that is at the forefront of technology in the pulp industry. Particularly in this area profound process engineering and know-how is necessary in order to achieve the desired effect with all necessary safety measures ensured.

ZPR MERCER ROSENTHAL:

ZPR is part of the North American Mercer International Group, one of the world’s leading manufacturers of long fiber pulp. The Mercer Rosenthal is located in Blankenstein, Thuringia, in one of the most tree-covered areas in Germany. With over 130 years of history, the company is now one of the most modern pulp mills in Europe. Mercer draws the greatest possible benefit from the valuable raw material wood. Cellulose and valuable biochemicals are obtained from the wood fiber. All other wood components are used to generate energy in the form of heat and bio-electricity. Mercer Rosenthal is constantly on the lookout for further solutions how the valuable resource wood can be used even more sustainably and with even greater added value.